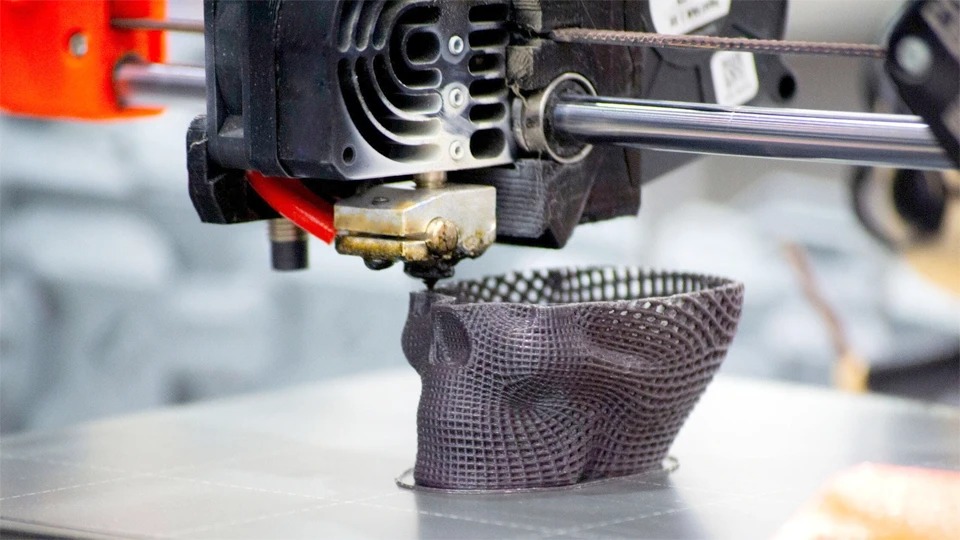

Early Detection for 3D Printing & CNC Machining

Our service provides a sophisticated, real-time early detection system for both 3D printing and CNC machining processes. This innovative solution is engineered to identify potential manufacturing anomalies and deviations at their earliest stages, significantly minimizing material waste and reducing the need for extensive rework. Its application spans across critical sectors such as aerospace, medical device manufacturing, automotive, and high-precision rapid prototyping, ensuring optimal part quality and process integrity from inception to completion.

Core Service Components

The service is built upon a foundation of advanced technological elements designed for comprehensive oversight. It encompasses real-time data acquisition from manufacturing equipment, sophisticated analytics engines that process vast datasets, and predictive modeling capabilities to forecast potential issues. Key stages involve continuous data ingestion, in-depth algorithmic analysis, automated alert generation for detected anomalies, and detailed diagnostic reporting that provides actionable insights. The system integrates seamlessly with existing sensor networks and leverages custom-developed software modules for unparalleled precision.

Underlying Technologies and Methodologies

At the heart of our detection system lies a robust suite of cutting-edge technologies and proven methodologies. We employ advanced machine learning (ML) algorithms and artificial intelligence (AI) to discern subtle patterns indicative of impending issues. IoT sensor networks are strategically deployed to gather precise operational data, which is then processed using high-performance cloud computing infrastructure. Our approach incorporates statistical process control (SPC) for baseline deviation analysis, coupled with sophisticated pattern recognition and deep learning techniques to accurately identify complex defects.

-

Real-time Process Monitoring: Continuous, granular oversight of critical manufacturing parameters throughout every stage of the 3D printing or CNC machining cycle.

-

Predictive Anomaly Identification: Automated, proactive detection of process deviations and material inconsistencies before they culminate in component defects.

-

Automated Diagnostic Reporting: Generation of clear, concise reports detailing identified issues, their potential root causes, and recommended corrective actions.

-

Parameter Optimization Suggestions: Providing intelligent insights and recommendations for fine-tuning machine settings to enhance overall production output and consistency.

-

Material Integrity Assessment: Ongoing evaluation of raw material behavior, consistency, and structural response during the entire build or cutting process.

Adherence to Quality Standards and Protocols

Our early detection service operates under stringent adherence to internationally recognized quality standards and rigorous operational protocols. We comply with ISO 9001 for quality management systems, alongside industry-specific benchmarks such as AS9100 for aerospace applications and ISO 13485 for medical device manufacturing. Our protocols mandate strict data integrity, secure handling of all process information, and the use of validated algorithms that undergo rigorous testing and verification to ensure unparalleled accuracy and unwavering reliability in all detection processes.

Seamless Integration and Adaptation

The ProtoCheck early detection service is designed for effortless integration into diverse existing manufacturing ecosystems. It achieves seamless connectivity with a wide array of machine controllers, including both CNC and 3D printing platforms, as well as enterprise resource planning (ERP) and manufacturing execution systems (MES). Adaptation is facilitated through customizable sensor configurations, flexible API-driven connectivity, and adjustable alert thresholds, allowing for precise alignment with specific operational requirements. Implementation is executed through a phased deployment strategy, ensuring minimal disruption to ongoing production activities.

Robust Control, Security, and Optimization Framework

Our system provides comprehensive control through a centralized dashboard, offering a unified view of all monitored processes. Configurable alert systems and granular user access controls ensure that relevant personnel receive timely notifications and maintain appropriate oversight. Security is paramount, with end-to-end encryption, robust authentication mechanisms, and regular security audits safeguarding all data. Compliance with global data privacy regulations is strictly maintained. Continuous optimization is achieved through algorithm refinement and feedback loops, consistently enhancing detection accuracy and resource allocation efficiency.

Extensive Compatibility with Existing Solutions

The ProtoCheck early detection service is engineered for broad interoperability, ensuring seamless compatibility with a diverse range of CAD/CAM software platforms and various machine brands and models across the manufacturing landscape. Its open architecture facilitates straightforward integration with existing quality management systems, supply chain platforms, and post-processing solutions, creating a cohesive and efficient operational ecosystem. This design philosophy ensures that our service augments, rather than disrupts, your current technological investments, maximizing synergy and operational fluidity.

Scalability and Future-Proof Development

Built on a cloud-native architecture, our service offers inherent scalability, effortlessly accommodating expanding production volumes, integrating new manufacturing equipment, and adapting to evolving operational demands. This design ensures that your investment remains relevant and effective as your business grows. We maintain a strong commitment to continuous research and development, actively incorporating emerging sensor technologies and integrating advanced AI models. This forward-looking approach ensures that the ProtoCheck service remains at the forefront of manufacturing innovation, future-proofing your production capabilities.

Assurance of Reliability and Technological Maturity

The ProtoCheck early detection service represents a culmination of advanced engineering and deep industry insight, delivering a robust and technologically mature solution. It offers a profound enhancement to operational stability, ensures superior part consistency, and empowers informed decision-making across all manufacturing stages. Our unwavering commitment to cutting-edge precision and absolute reliability underscores every aspect of this service, providing an indispensable tool for maintaining peak performance in complex production environments.