Automated Geometry Correction for Production Models

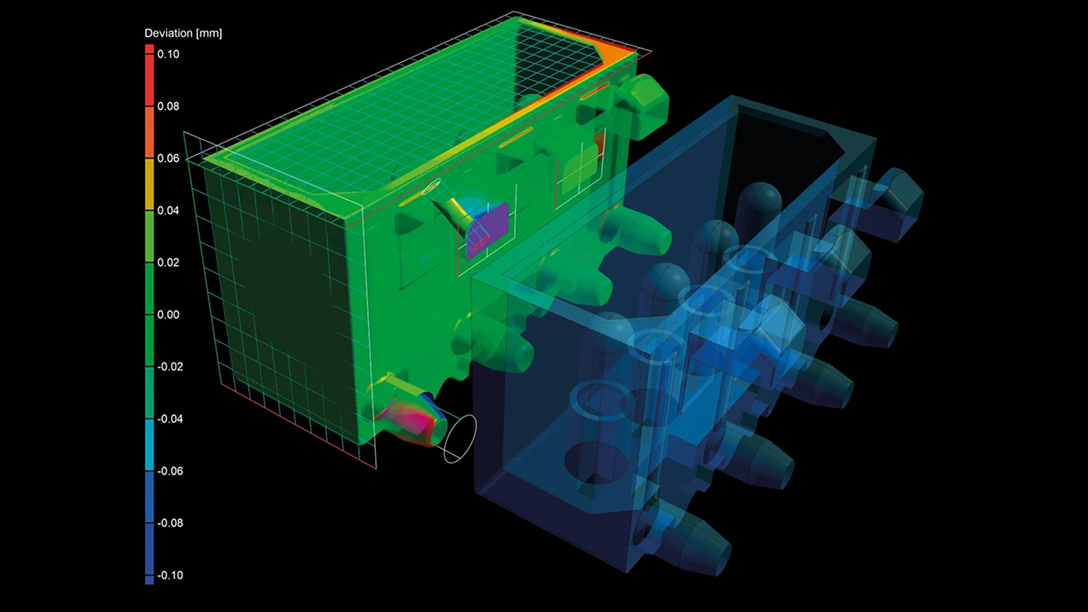

ProtoCheck's Automated Geometry Correction service refines 3D models for manufacturing with unparalleled precision. It ensures design integrity and production readiness by automatically identifying and rectifying geometric imperfections, bridging the critical gap between CAD design and physical fabrication. This essential service is crucial for industries requiring high precision, minimizing costly errors and accelerating time-to-market for complex products.

Core Elements of Our Geometry Correction Service

The service encompasses several core components designed for comprehensive model optimization. It begins with an initial model analysis for defect detection, followed by the intelligent application of advanced algorithms for correction. This process includes rigorous validation against engineering specifications, culminating in the generation of optimized, production-ready models. Key stages involve efficient data ingestion, automated diagnostics, precise geometric reconstruction, and final quality assurance checks to guarantee accuracy.

Leveraging Advanced Technologies and Methodologies

Our solution leverages advanced computational geometry algorithms, employing machine learning for robust pattern recognition of common defects, and integrating with leading CAD kernels for seamless operation. We utilize parametric modeling techniques for adaptive corrections and deploy cloud-based processing for efficient handling of complex models. This combination ensures rapid, accurate, and scalable transformations, maintaining the highest standards of geometric fidelity.

- Automated Defect Identification: Systematically scans 3D models to detect geometric anomalies like gaps, overlaps, inverted normals, and non-manifold edges.

- Precision Surface Reconstruction: Intelligently rebuilds flawed surfaces and volumes, ensuring watertight models suitable for downstream manufacturing processes.

- Tolerance-Based Correction: Applies corrections within user-defined or industry-standard tolerances, preserving design intent while enhancing manufacturability.

- Topology Optimization: Streamlines model topology, removing redundant features and simplifying complex geometries without compromising structural integrity.

- Output Format Generation: Produces corrected models in various industry-standard formats, ready for CAM, CAE, or 3D printing applications.

Adherence to Stringent Quality Standards and Protocols

ProtoCheck adheres to rigorous quality protocols, including principles derived from ISO 9001 for process management. Our geometric corrections comply with industry-specific standards such as ASME Y14.5 for Geometric Dimensioning and Tolerancing (GD&T) and various CAD/CAM interoperability guidelines. Each corrected model undergoes a multi-stage validation process, ensuring absolute fidelity to the original design intent and suitability for immediate production.

Seamless Integration into Existing Infrastructures

Implementing our Automated Geometry Correction service is designed to be a streamlined process. We offer flexible integration options, including API access for direct incorporation into existing PLM/PDM systems, or as a standalone desktop application. Our dedicated team provides comprehensive support during setup, ensuring seamless data flow and minimal disruption to your current engineering and design workflows.

Comprehensive Control, Security, and Optimization Measures

Our system incorporates robust version control for every model iteration and maintains a complete audit trail of all corrections applied. Data security is paramount, utilizing end-to-end encryption and stringent access controls to protect sensitive intellectual property. Continuous optimization algorithms are employed to enhance processing speed and accuracy, adapting dynamically to evolving geometric complexities and manufacturing demands.

Broad Compatibility with Diverse Solutions

The service is designed for broad compatibility, supporting major CAD file formats such as STEP, IGES, Parasolid, and native formats from SolidWorks, CATIA, and NX. It seamlessly integrates with leading CAE analysis tools, CAM software, and additive manufacturing platforms. This extensive interoperability ensures a cohesive digital thread across the entire product development lifecycle, enhancing overall workflow efficiency.

Scalability and Continuous Future Development

Built on a highly scalable architecture, our service efficiently handles fluctuating volumes of models, from individual parts to large assemblies, without compromising performance or accuracy. We maintain an active roadmap for continuous improvement, incorporating valuable feedback and integrating emerging manufacturing technologies. This commitment ensures the service evolves consistently with industry needs and advances in geometric processing.

ProtoCheck's Automated Geometry Correction represents a technologically mature and profoundly reliable solution for ensuring production readiness. Its advanced technology and adherence to stringent standards provide engineers with unparalleled confidence in their digital models, significantly streamlining manufacturing preparation and validation processes.