Unlocking Efficiency: The Power of Parametric Design in Manufacturing

Parametric design represents a fundamental shift in how products are conceived and manufactured. Moving beyond static 2D drawings or fixed 3D models, it leverages mathematical relationships and algorithms to define design elements. This approach allows for dynamic adjustments, where altering one parameter automatically updates related features, ensuring consistency and adaptability across complex systems. It's a powerful tool for modern engineering challenges.

Historically, design iterations were time-consuming, often requiring extensive manual redrawing for every minor change. Early CAD systems offered digital drafting, but parametric modeling introduced a new dimension of intelligence. This evolution from simple geometry to rule-based design marked a significant leap, enabling engineers to explore a broader spectrum of possibilities with unprecedented speed and accuracy, transforming the initial stages of product creation.

The underlying principle of parametric design lies in its ability to capture design intent. Instead of just describing what a design looks like, it defines how it behaves when certain conditions change. This capability is crucial for industries demanding high levels of customization and efficiency. It lays the groundwork for automated design processes, reducing human error and freeing up valuable resources for more innovative tasks, a cornerstone of advanced manufacturing.

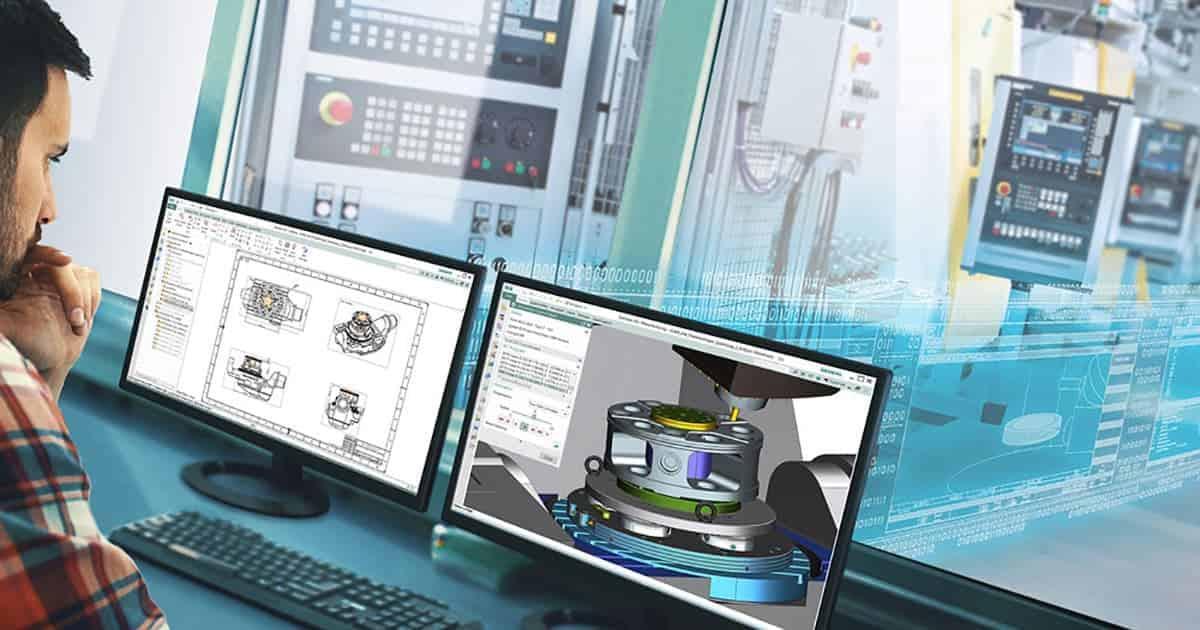

The advent of sophisticated computational tools has further amplified the impact of parametric methodologies. These tools allow for the integration of performance simulations directly into the design phase, enabling real-time feedback on structural integrity, material usage, and assembly processes. This seamless flow of information shortens development cycles and ensures that designs are not only aesthetically pleasing but also optimally functional and manufacturable from the outset.

Key Insights from Parametric Design Adoption:

- Enhanced Design Flexibility: Studies consistently show that parametric systems significantly expand the range of design variations possible, fostering greater innovation.

- Accelerated Iteration Cycles: Research indicates a substantial reduction in the time required for design modifications, leading to faster product development timelines.

- Improved Customization Potential: Literature highlights how parametric models enable efficient mass customization, meeting diverse market demands without extensive re-engineering.

Navigating the Parametric Landscape in Production

The transformative power of parametric design extends far beyond initial conceptualization. In manufacturing, it facilitates a more agile and responsive production ecosystem. By linking design parameters directly to manufacturing processes, changes can be propagated automatically, minimizing errors and reducing the need for costly manual adjustments on the factory floor. This creates a highly adaptive and efficient workflow.

One of the most compelling aspects is its role in enabling mass customization. Consumers increasingly demand personalized products, and traditional manufacturing struggles to meet this without incurring significant costs. Parametric design allows for the generation of unique product variants from a single master model, simply by adjusting input parameters, making bespoke production economically viable for ProtoCheck's clients.

However, adopting parametric design is not without its considerations. The initial investment in software and, more importantly, in training personnel, can be substantial. Designers and engineers need to shift their mindset from drawing fixed geometry to thinking in terms of relationships and rules. This foundational change requires a commitment to upskilling and embracing new methodologies for long-term benefits.

Furthermore, the quality of the initial parametric model is paramount. A poorly constructed model, with ill-defined relationships, can lead to complex issues down the line, negating many of the intended advantages. Therefore, meticulous planning and a deep understanding of the product's functional requirements are essential during the model creation phase. This front-loading of intelligence is key to sustained success.

Despite these challenges, the long-term operational advantages are undeniable. Parametric design fosters a higher degree of consistency and quality in manufactured goods. It allows for rigorous validation of design choices through integrated simulation tools, ensuring that products perform as intended before physical prototypes are even created. This predictive capability significantly reduces material waste and rework, enhancing overall resource utilization.

The integration of parametric design with advanced manufacturing technologies, such as additive manufacturing or CNC machining, unlocks unprecedented capabilities. Complex geometries, once impossible or prohibitively expensive to produce, become feasible. This synergy allows companies like ProtoCheck to push the boundaries of product innovation, delivering superior performance and novel functionalities to the market.

Future Pathways with Parametric Design:

- Streamlined Development Cycles: Parametric design dramatically shortens the time from concept to production, allowing faster market entry for novel products.

- Optimized Resource Use: By enabling precise material calculations and reducing rework, it leads to more sustainable and efficient manufacturing practices.

- Empowered Innovation: It frees designers to explore complex geometries and functionalities, pushing the boundaries of what's possible in product engineering.

Comments ( 0 )

Leave a comment