Elevate Your Production: Seamless 3D Model Validation

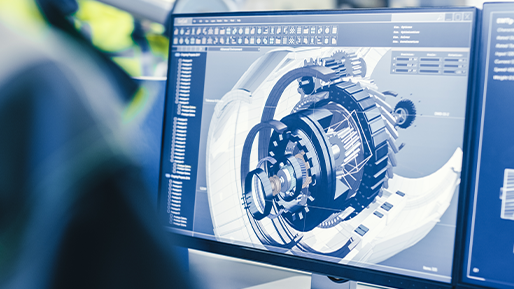

In today's fast-evolving industrial landscape, the reliance on 3D models is ubiquitous, forming the backbone of design, engineering, and manufacturing processes. From intricate aerospace components to consumer electronics and medical devices, these digital representations are critical. However, the sheer complexity and increasing scale of modern projects introduce significant challenges, making the integrity of these models paramount.

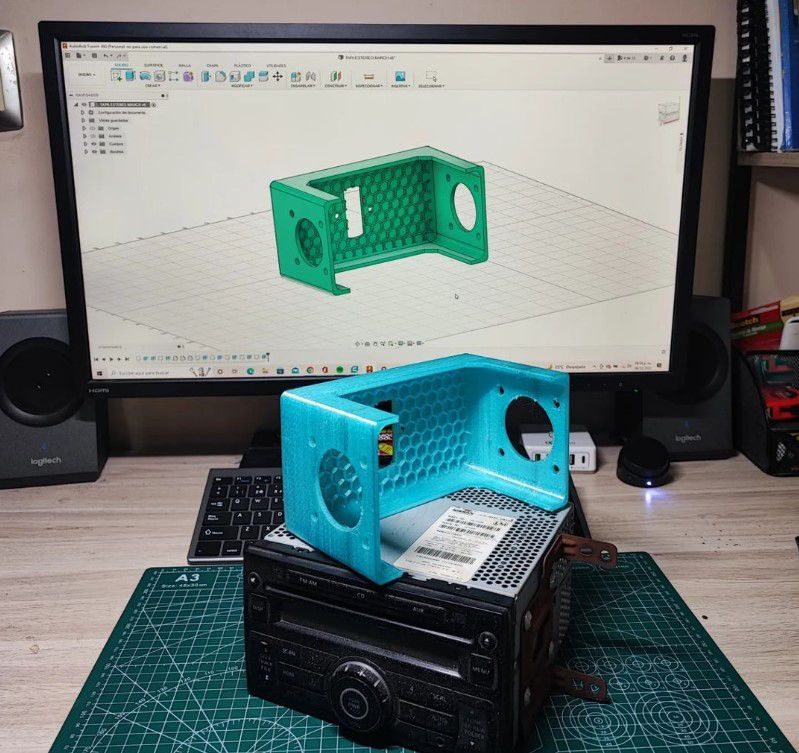

Historically, validating 3D models often involved manual checks and iterative physical prototyping, a process that was both time-consuming and resource-intensive. While effective to a degree, this approach frequently led to late-stage error detection, causing costly redesigns and delays in production schedules. The limitations of traditional methods underscored a growing need for more sophisticated and efficient validation techniques.

Previous research and industry experience consistently highlight that even minor inaccuracies in a 3D model can cascade into major issues down the production line. These can range from assembly failures and material waste to compromised product performance and safety concerns. The digital thread, connecting design to final product, is only as strong as its weakest link – often, an unvalidated model.

The drive towards digital transformation and Industry 4.0 has further amplified the demand for robust model validation. As companies embrace advanced manufacturing techniques like additive manufacturing and automated assembly, the prerequisite for flawless digital assets becomes non-negotiable. Ensuring geometric accuracy, adherence to specifications, and overall model health is no longer a luxury but a fundamental requirement for operational excellence.

Key Observations from Industry Literature

-

Early-stage 3D model validation significantly reduces the potential for downstream errors, fostering smoother production workflows and optimizing resource utilization.

-

The absence of comprehensive model integrity checks can lead to substantial rework, impacting timelines and the overall efficiency of manufacturing cycles.

-

There is a clear and increasing industry-wide need for automated, integrated solutions that can seamlessly verify 3D models across various design and production platforms.

Analyzing the Path to Flawless Production ✨

The transition from manual to automated validation represents a pivotal shift in how industries approach quality assurance. Manual checks, while offering a human touch, are inherently susceptible to oversight, especially with complex geometries and large assemblies. This human element introduces variability and often means that errors are only discovered much later, when their rectification becomes far more intricate and costly.

Automated validation tools, conversely, offer unparalleled consistency and speed. By employing sophisticated algorithms, these systems can rapidly scan models for geometric inconsistencies, topological errors, missing data, and deviations from specified tolerances. This allows for proactive identification of issues, enabling designers to correct flaws at their source, long before they manifest in physical prototypes or production runs.

One of the primary challenges in implementing automated validation lies in its seamless integration into existing design and manufacturing ecosystems. Many organizations operate with diverse software tools and legacy systems, making interoperability crucial. A truly effective validation solution must be able to communicate effectively across different platforms, ensuring a cohesive digital workflow.

Consider the benefits of a system like ProtoCheck, which is engineered to provide comprehensive model verification. Such platforms empower engineers and designers to maintain high standards of data integrity throughout the entire product lifecycle. By ensuring that every digital asset is precise and compliant, organizations can build a foundation of reliability for their physical products.

Furthermore, the insights gained from automated validation extend beyond simple error detection. The data collected can inform design best practices, identify common pitfalls, and even contribute to predictive modeling for future projects. This continuous feedback loop enhances organizational learning and fosters an environment of continuous improvement in digital asset creation.

The concept of a "digital twin" underscores the importance of this precision. For a digital twin to accurately represent its physical counterpart, the underlying 3D model must be impeccable. Any flaw in the digital representation will propagate to the twin, undermining its utility for simulation, analysis, and operational monitoring. Flawless model integrity is therefore a cornerstone of this advanced paradigm. By leveraging tools that offer advanced capabilities, such as those found in ProtoCheck, organizations can achieve a new level of operational efficiency and product quality.

Key Takeaways for Advancing Production 💡

-

Embracing advanced 3D model validation is not merely about error correction; it's about establishing a culture of proactive quality assurance and operational excellence.

-

Implementing integrated validation solutions transforms production capabilities, enabling faster iterations, reduced waste, and enhanced product reliability.

-

The future of advanced manufacturing hinges on the integrity of digital assets, making seamless and automated model validation an indispensable component of modern industrial strategy. The continuous pursuit of perfection in digital models is paramount, and with solutions like ProtoCheck, businesses are well-equipped to meet these rigorous demands.

Comments ( 6 )

Sage Murray

Thank you for your kind words! We believe that fostering a proactive approach is crucial for modern manufacturing, and early validation is indeed a cornerstone of that strategy.

Eliza Green

I found the points about integration into existing workflows particularly relevant. It's a significant hurdle for many companies, and understanding how solutions address this is key.

Dean Cook

You've highlighted a very important aspect. Seamless integration is a core focus for advanced validation tools, ensuring they enhance rather than disrupt current operational pipelines.

Leonard Crawford

The connection between flawless models and the 'digital twin' concept really resonated with me. It clarifies why model integrity is so fundamental for future technologies.

Harper Hernandez

We're glad that connection was clear! The integrity of digital assets is absolutely foundational for the success of digital twin initiatives and broader Industry 4.0 advancements.

Zachary Cunningham

This article perfectly articulates the shift towards proactive quality in 3D production. It's great to see the emphasis on early validation preventing major issues.