Beyond the Screen: Bridging the Gap Between Design and Production

For decades, the journey from a brilliant design concept to a tangible product often felt like navigating a chasm. Designers meticulously crafted visions on screen, only for those ideas to encounter significant hurdles when handed over to production teams. This traditional "throw-it-over-the-wall" approach frequently led to misunderstandings, rework, and ultimately, compromises on the initial creative intent. The disconnect was a fundamental gap in communication and shared understanding.

In today's fast-paced landscape, the complexity of product development has escalated dramatically. Modern products demand intricate coordination across diverse disciplines. The expectation for flawless execution and rapid iteration means that isolated workflows are no longer sustainable. Organizations are increasingly recognizing the critical need for a more integrated, holistic approach that unites creative ideation with practical execution from a project's start.

Early attempts to bridge this divide often faced challenges rooted in differing terminologies, specialized toolsets, and distinct departmental objectives. Designers focused on user experience and aesthetics, while engineers grappled with technical feasibility, material constraints, and manufacturing processes. These divergent perspectives, while essential, frequently created friction. Understanding these historical barriers is crucial for developing effective modern solutions.

The emergence of design systems and collaborative platforms marked a significant turning point. These innovations provided foundational steps towards a shared language and common ground, allowing teams to reference consistent components and guidelines. This shift fostered an environment where design principles could be translated into production realities with greater fidelity, laying the groundwork for truly integrated development cycles.

Key Observations from Research:

- Early integration of production constraints into the design process significantly reduces rework, saving valuable resources and accelerating project timelines.

- The establishment of shared visual languages and component libraries fosters unparalleled consistency and efficiency across diverse development teams.

- Implementing iterative feedback loops between design and engineering teams accelerates innovation and allows for proactive problem-solving before costly issues arise.

Analyzing the Integration Imperative:

The impact of siloed teams extends beyond mere inefficiency; it can lead to products that miss market opportunities or fail to meet user expectations. When design concepts are developed in isolation, without an understanding of production limitations, the final output often deviates from the initial vision. This can result in costly redesigns, delayed launches, and a diminished overall product experience, underscoring the need for a unified approach.

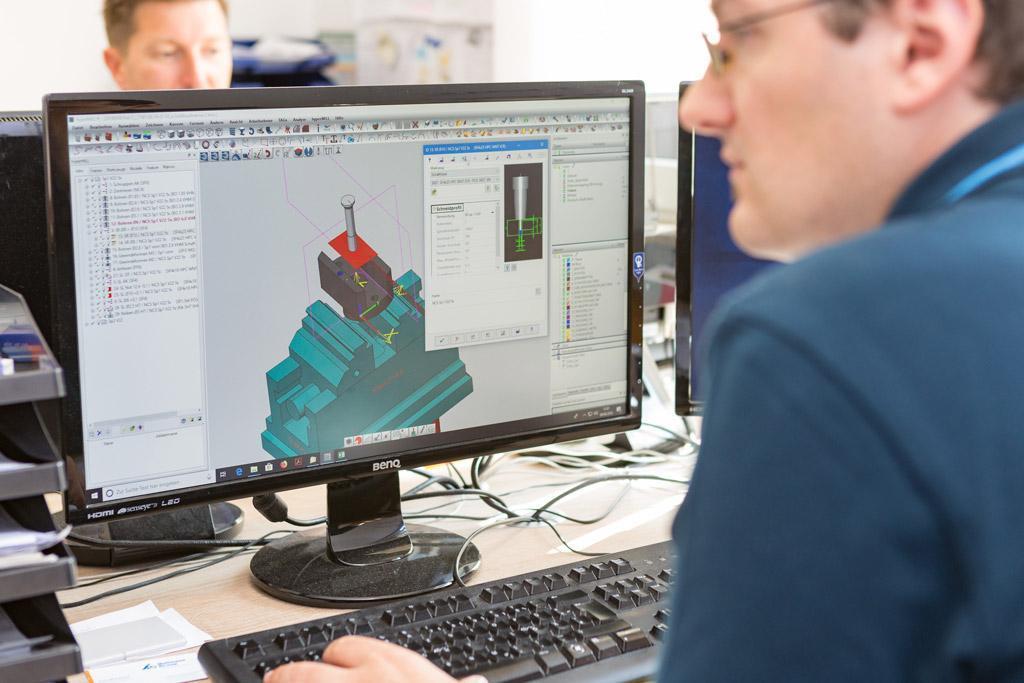

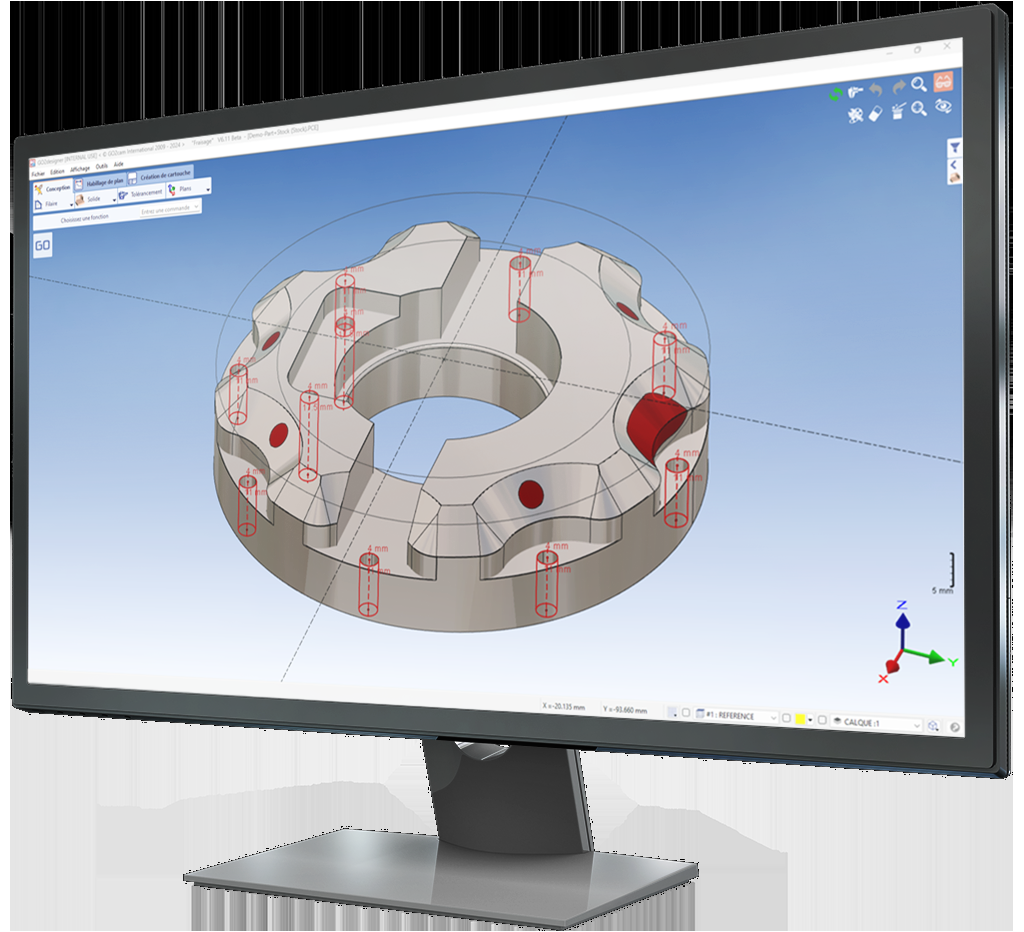

Technology plays a pivotal role in bridging this divide. Advanced tools for prototyping, simulation, and project management now enable real-time collaboration and shared understanding. These platforms allow designers to visualize how their concepts will translate into physical or digital realities, while engineers can provide immediate feedback on feasibility. This digital handshake is essential for maintaining fidelity from concept to completion.

Beyond tools, fostering a culture of empathy and mutual respect is paramount. Designers must understand engineering challenges, and engineers must appreciate design intent. This requires open communication, regular cross-functional meetings, and shared objectives. When teams value each other's expertise, the collective problem-solving capacity is greatly enhanced, leading to more robust and thoughtful product solutions.

Adopting a "design-for-manufacturability" mindset from the outset is not just a best practice; it's a strategic imperative. This approach means considering production processes, material availability, and assembly methods during the initial design phases. Companies like ProtoCheck empower teams to integrate these considerations early, ensuring that designs are not only innovative but also practical and efficient to produce, reducing downstream complications.

Despite the clear advantages, implementing these integrated workflows isn't without its challenges. Resistance to change, insufficient training on new tools, or a lack of strong leadership buy-in can derail even the most well-intentioned initiatives. Overcoming these hurdles requires a clear vision, consistent communication, and a commitment to continuous improvement across all levels of the organization, ensuring everyone is aligned.

Ultimately, organizations that successfully bridge the gap between design and production gain a significant competitive edge. They achieve faster innovation cycles, deliver higher-quality products, and cultivate more engaged, effective teams. This strategic integration transforms potential friction points into opportunities for synergy, leading to sustained organizational growth and a reputation for excellence in product development and delivery.

Key Takeaways and Applications:

- Enhanced product quality and user satisfaction through a cohesive, end-to-end development process that prioritizes both form and function effectively.

- Streamlined workflows and reduced development cycles, leading to faster market entry for innovative products and services.

- Fostering a more collaborative and engaged team environment, where designers and engineers work in harmony, maximizing creativity.

Comments ( 4 )

Ava Hudson

Glad to hear it resonates! Establishing that common ground is indeed a significant step towards smoother workflows. We believe ProtoCheck can be instrumental in this.

Veronica Cooper

The point about historical barriers due to differing toolsets is very accurate. It's often overlooked how much technology can both separate and unite teams. How do you see companies overcoming the initial investment in new collaborative tools?

Clayton Bradley

That's a valid point. The initial investment can be a hurdle, but the long-term gains in efficiency and product quality typically far outweigh it. Focusing on incremental adoption and demonstrating early wins can help build internal support.

Arthur Vasquez

This article really highlights the crucial need for design and production teams to work together. The emphasis on shared language and early integration resonates deeply with my experience. Great insights!